Machine Type:

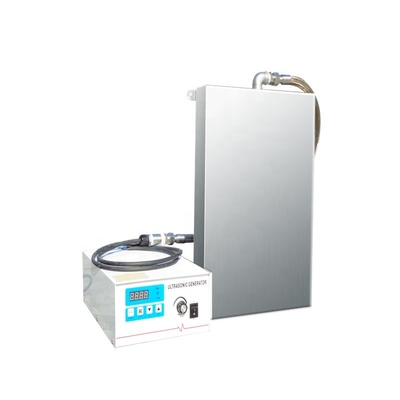

Industrial Ultrasonic Cleaner

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Construction Works , Energy & Mining, Food & Beverage Shops, Advert

Showroom Location:

None

Video Outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

Ordinary Product

Warranty Of Core Components:

2 Years

Core Components:

PLC, Engine, Pump

Condition:

New

Fuel:

Electric

Use:

Degreasing

Cleaning Process:

Hot Water Cleaning

Cleaning Type:

Industrial Ultrasonic Cleaner

Material:

Metal / Coil, SS304 Or SS316

Power:

1800

Warranty:

1 Year, 2 Years

Size:

Customized Transducer Box

Ultrasonic Power:

1800W

Transducer Quantity:

36pcs

Frequency:

40 / 28 KHZ

Application:

Degrease

Name:

Transducer Generator

Used:

Engine Carbon Cleaning

After Warranty Service:

Video Technical Support, Online Support, Spare Parts

Local Service Location:

None

Certification:

Ce, RoHS

After-sales Service Provided:

Free Spare Parts

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!